Technical data

Comparison with other construction method

Advantage

| ●There is no need for drilling or hole alignment. ●During work "sparks, smoke, etc." does not occur. ●Do not use water etc. ●The inspection method is easy by visual observation. ●It is possible to work with inexperienced person without requiring skill. ●It corresponds to automation. ●Machine life is long ●The fastening strength is more stable than spot welding. ●The noise is small. ●Different materials and coating materials can be bonded. |

| Applications | JOISPND | Spot welding | Blind rivet | TOX |

|---|---|---|---|---|

| Pilot hole unnecessary |

○ | ○ | × | ○ |

| Fastening strength |

○ | ○ | × | × |

| Dissimilar | ○ | × | ○ | △ |

| Joining of paint and plating material |

○ | × | ○ | △ |

| Machine life is long | ○ | ○ | × | △ |

| Ease of automation | ○ | ○ | × | △ |

| Robot compatibility | ○ | ○ | × | ○ |

| Silence | ○ | △ | × | △ |

| There is no spark or smoke. |

○ | × | ○ | ○ |

Further details about rivet

It is a rivet which can obtain high strength on steel plate etc.

There are two types of rivet shaft diameters: 3.0 mm and 5.0 mm.

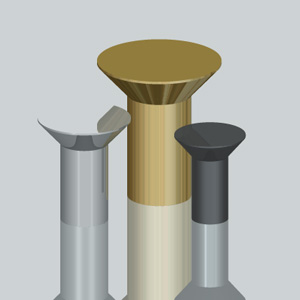

Outer shape (head shape)

The outer shape (head shape) has "flush head, flat head, pan head", which affects the appearance. The mainstream is a flush head, the other two are custom made items.

|

Hollow rivet whose flush head, the driving surface becomes a flat surface. |

Inner shape

The inner shape has "R type" and "P type".

| Schematic Drawing | Feature |

|---|---|

|

It is used when rivet which is widely used for general steel sheet needs strength. |

| Schematic Drawing | Feature |

|---|---|

|

It is suitable for joining of aluminum material with hollow rivet, which is used when the finish of the back side is required. |

※Rivets are heat treated and plated. Heat treatment is divided into 0 to 7 stages, and it is suppressed to Hv 600 at maximum.

※High carbon steel and stainless steel are used for rivet material. The kind of plating is usually galvanized, some with color painting on tin zinc plating or galvanizing.

※Special type is made to order.

Fastening strength

| Bade materiar type |

Base material thickness (mm) |

Total thickness (mm) |

Detachment strength (KN) |

Shear strength (KN) |

Use rivets |

|---|---|---|---|---|---|

| Galvanized steel | 1.0 | 2.0 | 3.05 | 3.4 | shaft diameter3.0×lenght5.0 |

| 2.0 | 4.0 | 7.35 | 11.0 | shaft diameter5.0×lenght8.0 | |

| 3.2 | 6.4 | 9.6 | 13.0 | shaft diameter5.0×lenght10.0 | |

| Stainless steel | 0.5 | 1.0 | 1.92 | 2.13 | shaft diameter3.0×lenght5.0 |

| Aluminum 5000 series |

1.2 | 2.4 | 2.0 | 3.0 | shaft diameter3.0×lenght5.0 |

| Aluminum 6000 series |

2.0 | 4.0 | 6.15 | 9.40 | shaft diameter5.0×lenght7.0 |

Usage

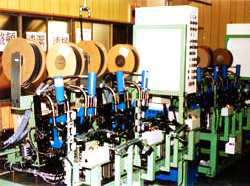

Usage example of system equipment

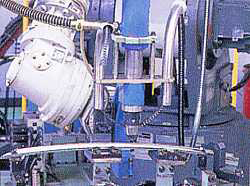

An orthogonal robot with |

An articulated robot that rivets |

Multi-system with |

Riveting by an |